The portable EM 6/8/10 Combo Seamless Siding Machines are the most user-friendly and durable machines ever built.

Eastside Machine Company pioneered and patented the first portable embossing seamless siding machine and is considered the #1 machine in roll-forming technology and reliability.

Our machines are all made in the USA, and we have more machines in use worldwide than all other companies combined.

Eastside Machine Co.’s siding machines feature our original self-contained embossing system, which applies a natural woodgrain texture to steel or aluminum coil.

- Heavy-duty steel frame for structural stability and forming consistency

- Quick and easy profile conversion

- Variable speed frequency drive

- Industrial nitrocarburized rollers

- Multi-profile guillotine

- Spool brake

- Weep hole and nail slot punches

- Extendable cutting table

- Chrome-plated shafts

- Emergency shut-off

- Push button control with tethered remote control and 10' cord

The EM 6/8/10 Combo Seamless Siding Machine is portable and capable of manufacturing over 40 seamless profiles ranging from a Horizontal 6" to Double 4" to a Double 5" Dutch profile.

Optional attachments like the, Half Board & Batten 4" and 5" and the Vertical Board & Batten 6", 8", or 10" are all great profile attachments that are available from Eastside Machine Co.

Our Quick Changeover Kit makes it easy to change the width of the profile running on the job. In less than 20 minutes, you can switch profiles within an attachment, so going from a Horizontal 6" profile to a Horizontal 8" profile is easy to do on-site.

Eastside Machine Co.'s machines easily switch complete attachments and are also jobsite-friendly. Attachment changeovers can be done in the field with just a little time and expertise.

Like the quick changeover kits, the flexibility of attachments on the jobsite gives you more options to sell and install.

This flexibility is important to have on the jobsite as more and more consumers are asking for multiple profiles, textures, and colors on building exteriors.

Portability, durability, and product flexibility are just three of many compelling reasons to choose an Eastside Machine Co. seamless siding portable roll-former.

To be successful in the siding industry you need to be productive with your assets. Down time costs you money!

With Eastside Machine Co. portable roll-formers, you’ll have peace of mind knowing that you bought an American-made and engineered roll-former that will make you more money.

Our team is experienced and ready to help you with any questions about machine support, use and install.

- EM 6/8/10 Combo Seamless Siding Machine

- Side Pull Guillotine Cutter

- 6 Adjustable Run-Out Stands

- 10 Run-Out Rails

- Coil Cradle with 3 Spools (Machine Can Hold up to 4 Spools – Not Recommended to Drive with 4)

- Double 3", 4", 5", 5" x 3", and 6" x 4" Attachment

- Double Dutch 4" and 5" Attachment

- Owner’s Manual

The Eastside Machine Company EM 6/8/10 jobsite roll-formers are built upon a heavy-duty steel frame for structural stability and forming consistency.

Industrial nitro-carburized (QPQ) steel rollers are used in all Eastside Machine Co. products.

Nitrocarburizing rollers allow for improved wear and lubricity, as well as strength and corrosion resistance.

Our proprietary embossing rollers, which apply an authentic and natural woodgrain texture to steel or aluminum coil, are artfully designed for pattern beauty and panel rigidity.

An extendable cutting table gives you the flexibility to make your cuts more precise.

Our portable siding machines operate with a 1.5 HP, 115 Volt, 20 Amp electric motor and have variable speed frequency drive.

This allows our seamless siding machines an infinitely adjustable forming speed from 1' to 60', giving you the ability to produce more than other machines on the market.

Our siding machines also come standard with an extendable remote switch with forward and reverse, allowing machine operation from outside the trailer.

Eastside Machine Co. knows the importance of making loading and unloading coils as simple and safe as possible.

With siding machines from Eastside Machine Co., your installers/operators can load and unload coils without using a forklift, like most portable siding machines.

An accessory coil loading system can be mounted to your enclosed siding trailer and can effortlessly lift coils up to 2,500# in a matter of minutes using a 110 Volt winch.

Safety is very important at Eastside Machine Co., and it is something we take very seriously.

All our siding machines are equipped with an emergency shut-off button and a spool brake to control the coil when operating the machine.

Like all machines from Eastside Machine Co., our portable seamless siding machines come with operational training, technical support, and a five-year warranty.

| Machine Specifications (as shown) |

|

| Machine Dimensions: |

138" (L) x 33.5" (W) x 45" (Height with Spools) |

| Machine Weight: |

2,975# (1,980# Machine Plus Coil Cradle and 3 Spools) |

| Coil Widths: |

9 5/64", 10 5/8", or 13 1/4" (Other Options Available Upon Request) |

| Materials: |

Steel: 28–29 Gauge, Aluminum: 0.024-0.027 |

| Number of Forming Stations: |

9 Main Forming Stations |

| Operational speed: |

Variable to 60 ft/min |

| Shear/Cutter: |

Side Pull Guillotine |

| Power: |

1.5 HP, 110 Volt, Single Phase, 20 Amps |

| Controls: |

Push Button Tethered Remote Control with 10' Cord |

| Safety: |

Emergency Shut-off Switch at Entry End |

| Warranty: |

Five-Year Limited Warranty |

| Misc: |

Standard Panel Has a Nailing Hem or Nail Slot Punch and Weep Holes (Clip System Is Available Upon Request If Required) |

| Standard Profiles & Attachments |

|

|

Eastside Machine Company is the leader in the design and manufacturing of portable seamless siding machine.

We offer a number of attractive and unique profiles to offer your customers.

With over eight profiles that come standard with every Eastside Machine Co. EM 6/8/10 Combo Seamless Siding Machine, you will have our most popular profiles like the Double 4" and 6", the 6" x 4", and 5" x 3" profiles.

With Eastside Machine Co.’s Quick Changeover Kit, you can switch between the standard profiles at the jobsite with little downtime.

We also provide machine attachments to maximize the roll-forming options for your machine from Eastside Machine Co.

* Optional attachments

|

|

|

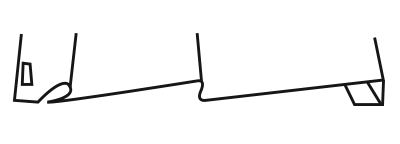

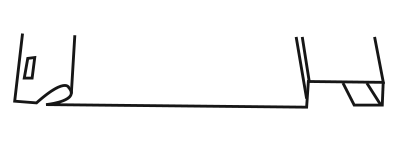

Traditional 6", 8", and 10"

View Example

|

|

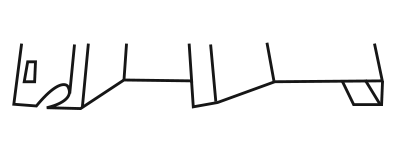

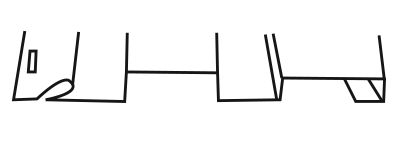

Double 3", 4", and 5" Attachment

View Example

|

|

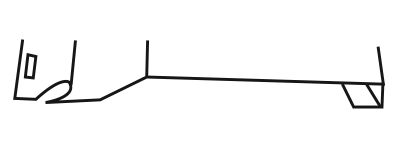

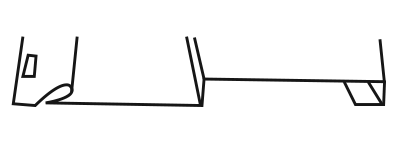

Double 4" and 5" Dutch Attachment

View Example

|

|

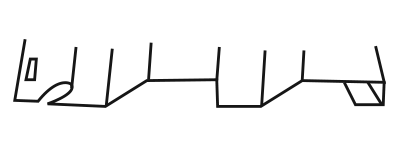

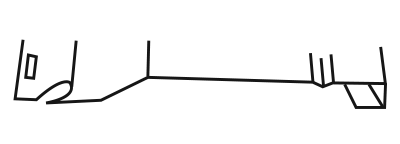

*Dutch Lap 6", 8", and 10" Attachment

View Example

|

|

*4" and 5" Colonial Dutch Attachment

View Example

|

|

*Vertical Board & Batten 6", 8", and 10" Attachment

View Example |

|

*Inverted Board & Batten 5" Attachment

View Example |

|

*Half Board & Batten 4" and 5" Attachment

View Example

|

|

*Beaded Dutch 6", 8", and 10" Attachment

View Example |

|

*Full Board & Batten (Plank or T-111) Attachment

View Example

|

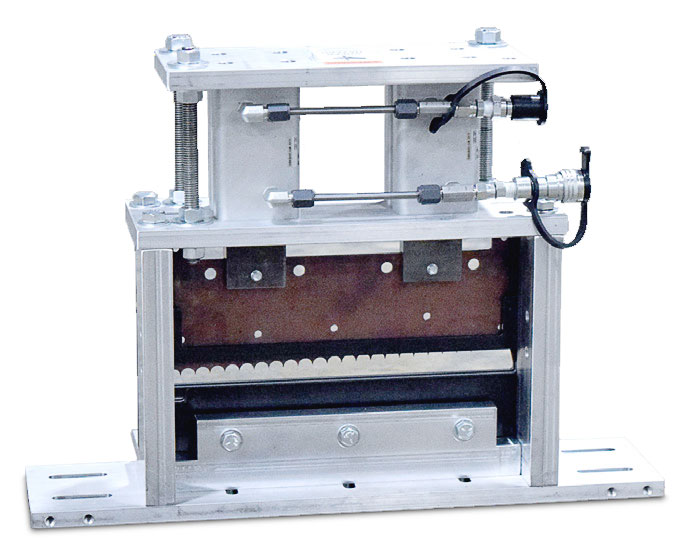

| Guillotine Cutter |

|

|

Eastside Machine Co. offers a multi-profile guillotine cutter standard on every seamless siding machine.

Industrial nitrocarburized steel blade gives a very desirable, clean cut.

The durability of the blade allows it to keep its sharp cutting edge, which minimizes maintenance; think of an Eastside Machine Co. guillotine cutter as comparable to the Ginsu knife's role in a kitchen.

|

| Unidrive System |

|

Unidrive is an AC Drive and Controller system with integrated Programmable Logic Control (PLC), and comes standard on all 2016 and newer EM 6/8/10 Combo Seamless Siding Machines.

The Unidrive converts single phase 110 Volt to 3-phase 220 Volt without the need of a transformer, resulting in a much more efficient use of power.

Unidrive benefits include: less power used, fewer circuit breaker, and GFI outlet problems and the ability to add the ATM system to your Eastside Machine Co. portable siding machine.

All siding machines come equipped with Unidrive. Benefits include more power efficiency, fewer tripped Circuit Breaker, no transformer, and the ability to add Auto Tape Measure (ATM) System.

Have an older Eastside Machine Co. EM 6/8/10 Combo Seamless Siding Machine with Softstart or Phase II Electrical? Unidrive can easily be added to 2015 and earlier models.

Just call Customer Service at (800) 234-7834 to learn more.

|

| Auto Tape Measure (ATM) System (Optional) |

|

|

The Auto Tape Measure (ATM) System will measure the panel length as it is formed.

Cut lengths can be set in the ATM without the need of measuring.

Batch any number of same-length panels to increase efficiency, all while adding convenience and accuracy on the jobsite.

ATM is also a great way to track the total number of feet used (like an odometer in a car) or the number of feet used during a single job.

ATM is an upgrade that can be added to any Eastside Machine Co. portable siding machine with the Unidrive system.

To learn more about the benefits of ATM and how it can help your install teams be safer and more efficient both in accuracy and speed, call Customer Service at (800) 234-7834.

|

| Siding Machine Accessories & Coil Sourcing |

|

|

Eastside Machine Co. and its affiliated companies are your one-stop shop for anything related to the siding industry.

We can help you finance your machine purchase, and you can buy coil and accessories from our sister company, EMCO Building Products.

We can also provide dealer and marketing support and have available programs for interested parties.

In addition, we also sell ReechCraft access equipment.

Our customers are very important to us and we look at every customer as a lifelong partner in the exterior products industry.

|

| Trailers |

|

|

Eastside Machine Co.'s siding machines are best suited in an enclosed and insulated 16' tandem axle trailer.

We sell quality, American-built, heavy-duty trailers designed for this industry.

Most people who purchase a trailer from Eastside Machine Co., purchase with a coil cradle for safe, easy, and forklift-free loading.

As far as standard features, our trailers include an 8' fluorescent interior light, two 110 Volt interior receptacles, a two-circuit panel with lifeline for a 110 Volt, one heavy-duty aluminum access ladder, and a 14' ladder rack and cat walk.

Our enclosed trailers are made of white aluminum (0.040 Gauge).

If you choose to purchase your enclosed seamless siding trailer from Eastside Machine Co., we can offer you custom graphics design and installation for your trailer.

Our in-house marketing department will work with you to create a truly eye-catching trailer graphic that is not only a key profit area for your business, but also serves as a billboard.

We also offer a dealer program, known as United States Seamless®. To learn more about United States Seamless, click here.

To learn about our dealer programs, marketing, graphic design, and install opportunities, ask one of our Customer Service team members or our Sales Associates.

|

Trailer Specifications & Features:

- 16' Enclosed Tandem Axel

- Overall Length: 20' (16' Plus 4' Tongue)

- Height: 8'

- Interior Height: 6' 6"

- Tandem 5,500# Torsion Axles (11,000# GVWR) 8-Bolt Hubs

- 235R85/16E Tires

- All-Wheel Electric Brakes and Breakaway Kit

- 16" On-Center Construction, 2" (H) x 6" (W) Box Frame

- Adjustable Tongue

- 24" Tall Aluminum Tread Plate

- Front Stone Guard

- Small Rear Door: 20" (H) x 35" (W) (Great for Cold Weather Operation)

- 30" Side Door with Camlock

- 3/4" Solid-core Plywood Floor

- Walls Lined in 3/8" Plywood

- Insulated Walls and Ceiling

- Double Rear Swing Out Cargo

- Doors (Offset Design)

| Coil Loading - No Forklift Required |

|

Easily load coil without using a forklift! This cradle mounts to all siding machines and can be customized for the seamless gutter machine.

|

| Rental Program |

|

|

Thinking about getting into the seamless siding business? Are you in the seamless business but not sure if you are ready to add another jobsite machine? Looking to run a special profile or attachment?

Consider Eastside Machine Company's Rental Program.

If you’d like to learn more about the rental opportunity, call (800) 234-7834 or email us at customer.service@eastsidemachine.com to learn more details and find out availability.

|

| Dealer Programs |

|

|

Whether or not you are already in the seamless siding business, we invite you to explore the opportunities to grow and expand your business with a United States Seamless® dealer program.

United States Seamless is a leading home improvement dealer opportunity for seamless steel siding, accessories, and seamless gutters products.

We're a goal-oriented company looking for self-motivated individuals in the home improvement or construction industry who can see themselves growing their business by partnering with a proven affiliate dealer program centered on best practices, great products, and a great brand name.

Whether or not you are already in the seamless siding business, we invite you to explore the opportunities to grow and expand your business with a United States Seamless® dealer program.

United States Seamless is a leading home improvement dealer opportunity for seamless steel siding, accessories, and seamless gutters products.

We're a goal-oriented company looking for self-motivated individuals in the home improvement or construction industry who can see themselves growing their business by partnering with a proven affiliate dealer program centered on best practices, great products, and a great brand name.

What kind of individual does it take to participate in a proven dealer organization like ours?

It takes individuals that are able to say "yes" to the following questions:

- Am I goal-oriented?

- Do I have the ability to lead employees and crews?

- Will I serve customers by providing them honest information in a professional manner?

- Do I want my customers to receive the best value for the money they will spend for quality home improvement products?

If you are interested in learning more about our affiliate opportunity, visit usseamless.com.

|

Eastside Machine offers three versatile cutter options for your seamless siding machine: the side pull guillotine cutter,

gearbox cutter, and hydraulic cutter. This guide outlines the unique benefits of each option to help you choose

the best fit for your needs.

| Side Pull Guillotine Cutter |

|

- Manual and simple

- Designed to cut 26- to 29-gauge steel material

- Universal upper blade design

- Lower blades are easily changed for each profile

- Easy to remove and adjust

|

| Gearbox Cutter |

|

- Uses gearbox technology and a cordless drill to operate

- No additional cords or power source required on site

- Designed to cut 26- to 29-gauge steel material

- Universal upper blade design

- Lower blades are easily changed for each profile

- Easy to remove and adjust

- Reduces physical fatigue caused by manual cutting

- Safe, effortless operation

- Can be added to your current machine

|

| Hydraulic Cutter |

|

- Two hydraulic cylinders maximize strength

and minimize travel, allowing for quicker, cleaner cuts

- Equipped with a small, stand-alone 110v hydraulic

pump and pendant control

- Designed to cut 26- to 29-gauge steel material

- Quick connect couplers for fast, simple removal

- Universal upper blade design

- Lower blades are easily changed for each profile

- Reduces physical fatigue caused by manual cutting

- Safe, effortless operation

- Can be added to your current machine

|